UniBlade2

UniBlade2

The next evolution in single

wiper blade systems

Higher run speeds, even less ink gelling and of course, incredible ink doctoring

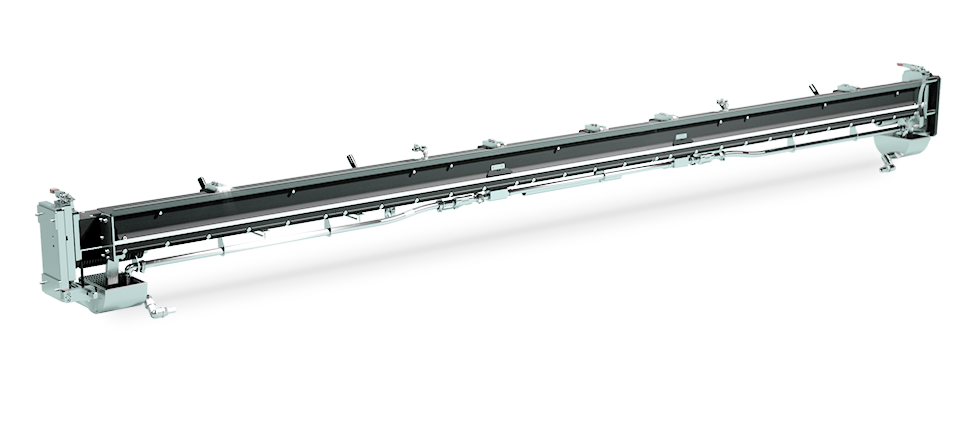

We’re all about improvement through innovation here at Absolute. UniBlade2’s ‘dynamic fluidics’ proves it, with higher run speeds and better-than-ever filling consistency, all thanks to the system’s carefully controlled ‘spiral’ ink flow.

Dynamic Fluidics takes

UniBlade2 to a whole new level

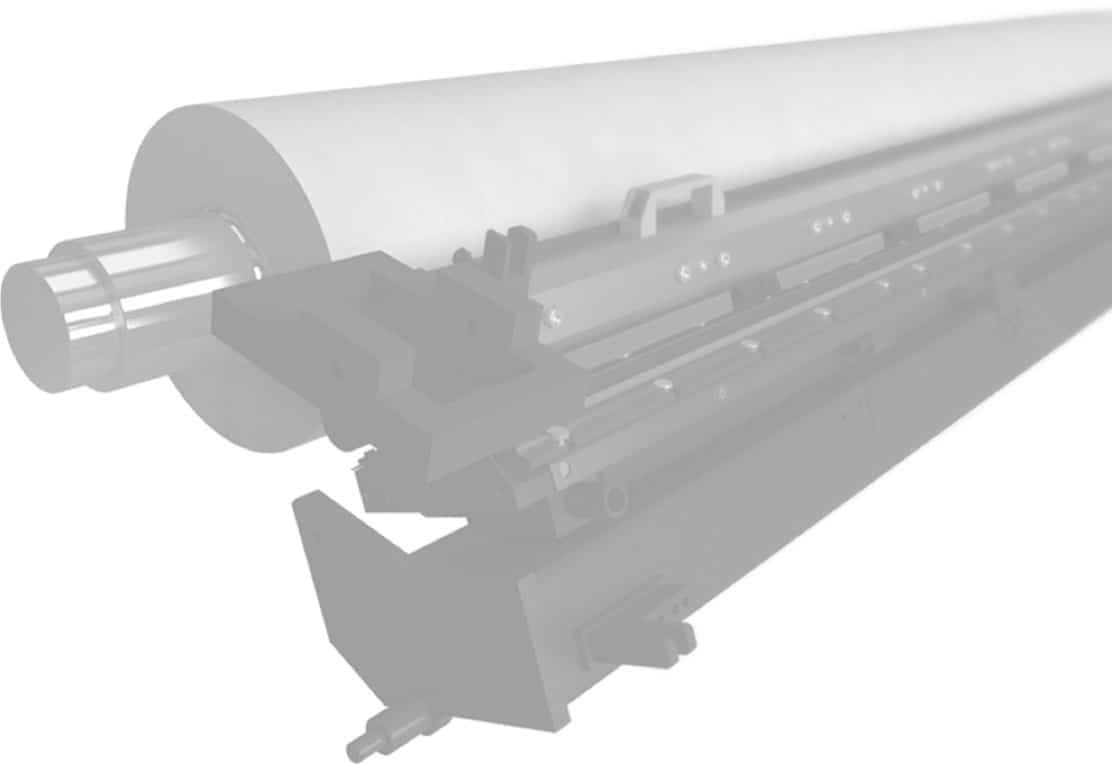

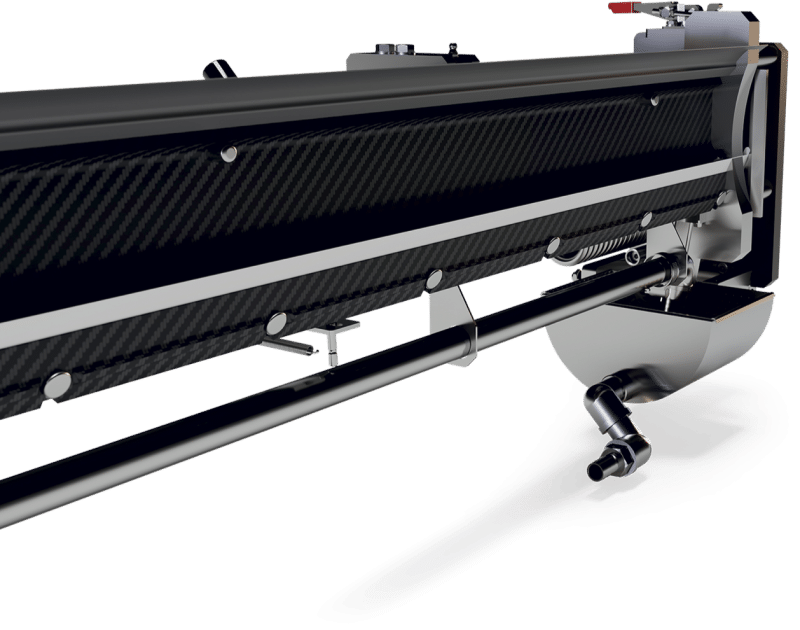

We worked with an expert in fluidics to redesign the wiper’s profile: nothing too radical, but the difference is clear. UniBlade2 uses a special curved back to create a cyclonic effect that significantly improves performance, both in terms of streamlining ink flow through the circuit and also accelerating distribution across the roller. Quickening the whole process means the ink is kept more stable and has less time to gel, and that brings one big benefit to your printing operation: longer runs with less intervention necessary.

Integral wash for

built-in efficiency

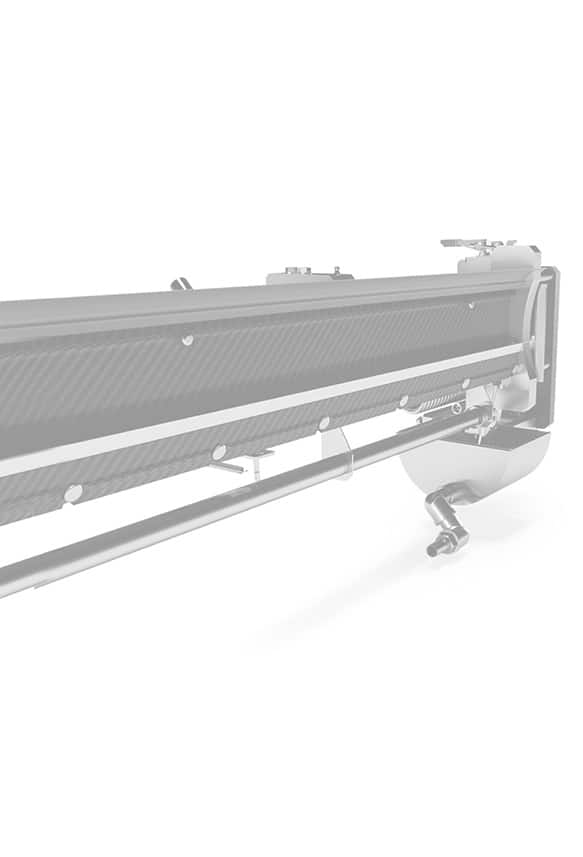

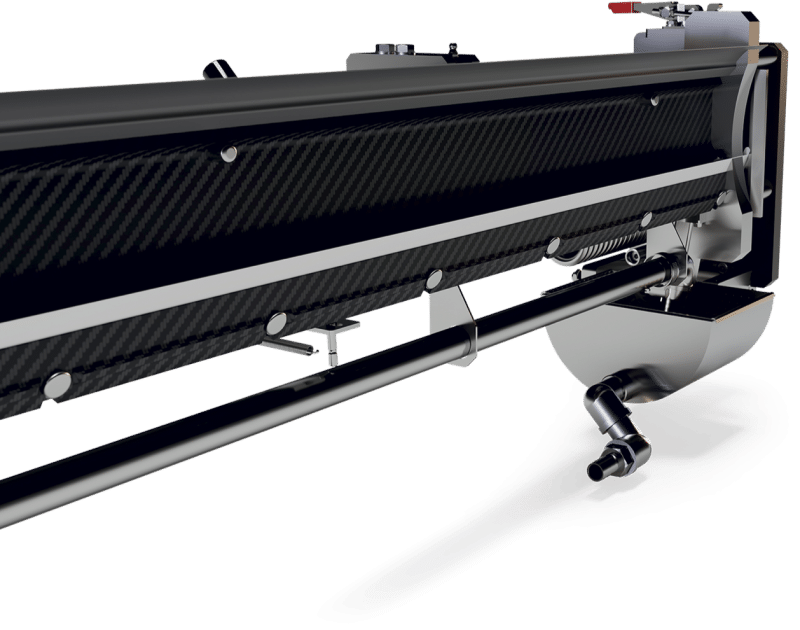

UniBlade2’s wash system is integral and automatic, so it saves crucial time between set-ups and gives you the chance to win back no-cost capacity. With downtime turned into work time, improved productivity is guaranteed, and even more so in bigger systems.

Just one consumable

Less downtime

One highly reliable consumable means you won’t have the risk of multiple causes of downtime.

Less to buy

Maintenance simplified with no small parts to give you headaches.

Less worry

Peace of mind for your operator who instead can turn attention to more pressing matters.

Ink flows in and out smoother and faster than ever.

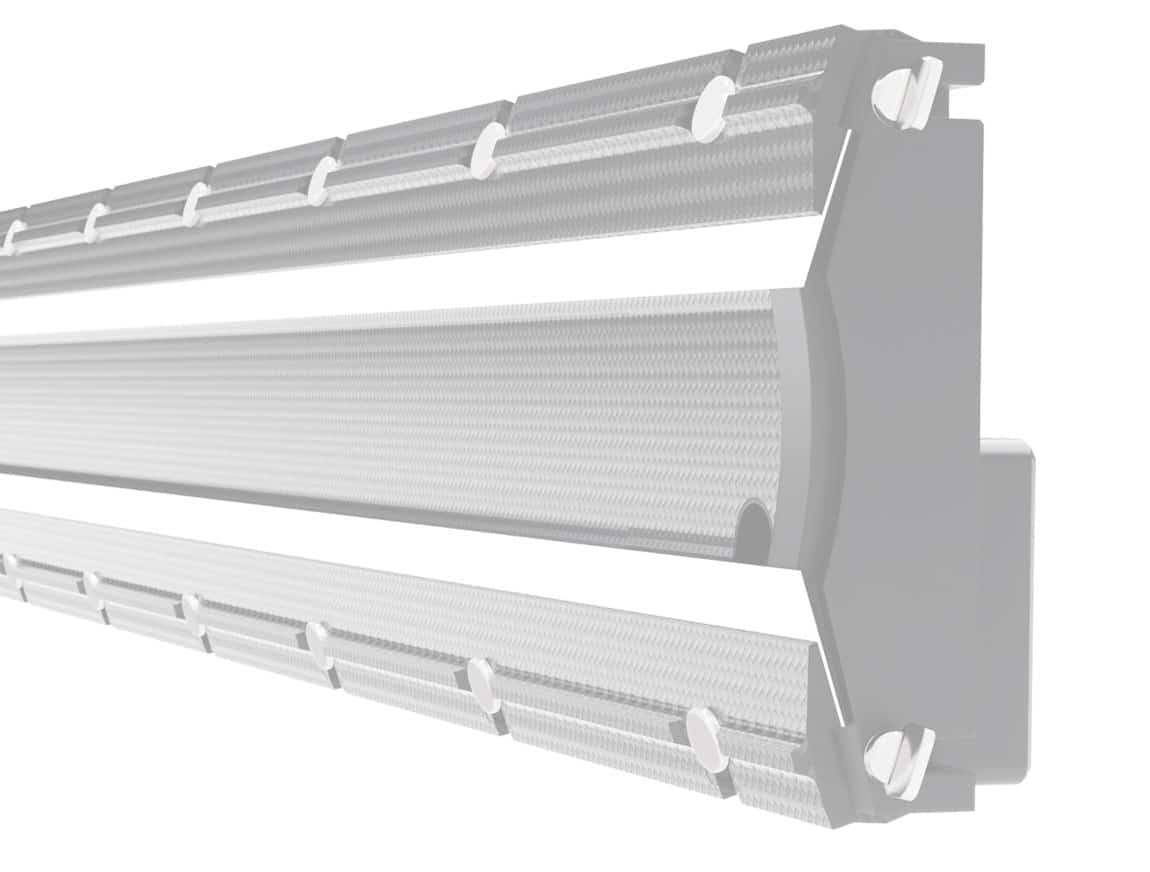

To reduce the risk of gelling and really optimise performance, we looked closer than ever at getting higher volumes of ink more quickly into the cavity, then out again through the returns. We've achieved it with a subtle but intelligent re-design, featuring baffles and all-new 'weir stops' to tightly control ink expulsion.

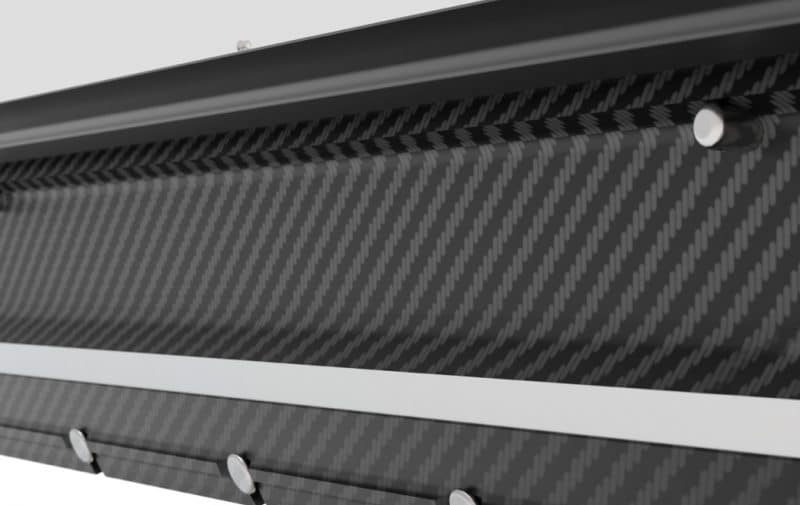

A carbon fibre quality that’s out of this world. Literally.

There’s nothing new about carbon fibre chambers, but UniBlade2’s construction uses moulded carbon fibre for exceptional strength and a grade that’s used in aerospace engineering.

“After great success of installing two Absolute print chambers on our 50” Langston a few years back, it was a no-brainer when we needed to replace our single-blade chamber on our 200” wide jumbo this year. Installation is simple and consumable parts minimal, and their 15-year corrosion guarantee is unmatched”

Acme Corrugated Box Co. Inc.